|

GERMAN

DEVELOPMENT:

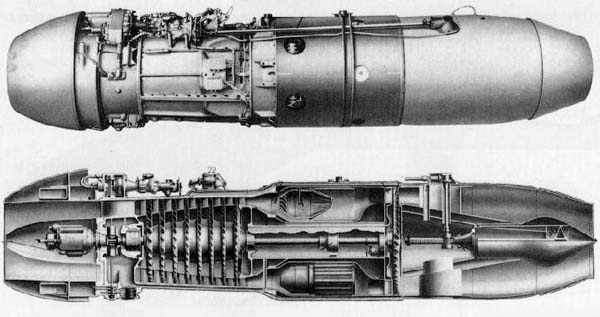

Work

on the gas turbine engine was going on in Germany concurrently with Whittle’s

work in Britain. Serious efforts toward aircraft jet propulsion were started

in the mid 1930s.

The

main German development took place in 1940, when Willi Messerschmitt produced

the Me 262, a 805 Km/h fighter, powered by two axial-flow engines, the

Jumo 109-004a. More than 1600 Me 262 fighters were built in the closing stages

of World War II, but they reached operational status too late to

challenge the overwhelming air superiority gained by the Allies seriously. The

main German development took place in 1940, when Willi Messerschmitt produced

the Me 262, a 805 Km/h fighter, powered by two axial-flow engines, the

Jumo 109-004a. More than 1600 Me 262 fighters were built in the closing stages

of World War II, but they reached operational status too late to

challenge the overwhelming air superiority gained by the Allies seriously.

TYPICAL

OPERATION:

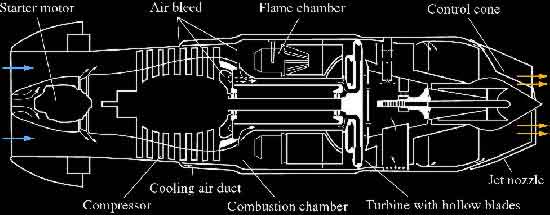

A

gas turbine engine is an internal combustion engine that consists of three main

parts:

The

axial-flow compressor

The

combustor

The

turbine

The

front, or inlet, duct is almost entirely open to permit outside air to enter the

front of the engine. The compressor works on this incoming air and sends it to

the combustion or burner section at high pressures. In the burner section, the

fuel, similar to kerosene, is sprayed and mixed with the compressor air. The

mixture is then ignited by devices similar to spark plugs. Extremely hot gas

streams from the combustor and escapes through the blades of the turbine,

spinning them at high speed. The turbine extracts most of the energy from the

gas stream and uses this energy to turn the compressor and the accessories.

After

leaving the turbine, there is still enough pressure left to force the hot gases

through the exhaust duct and jet nozzle at the rear of the engine at very high

speed.

AXIAL-FLOW

COMPRESSOR ENGINES:

The

Me 262 fighter used an axial-flow compressor engine, chosen because of its

ability to handle large volumes of airflow. Unfortunately, it is more

susceptible to external-object damage, it is expensive to manufacture and it is very

heavy in comparison with the centrifugal compressor with the same compression

ratio. The

Me 262 fighter used an axial-flow compressor engine, chosen because of its

ability to handle large volumes of airflow. Unfortunately, it is more

susceptible to external-object damage, it is expensive to manufacture and it is very

heavy in comparison with the centrifugal compressor with the same compression

ratio.

The

axial-flow compressor is made up of a series of rotating airfoils called rotor

blades, which are made up of an alloy of stainless steel containing Nickel (30%)

and Chromium (15%), and a stationary set of airfoils called stator vanes made up

of a particular steel alloy containing Chromium and Manganese. A stage is a row

of rotating and stationary blades. The entire compressor is made up of a series

of alternating rotor and stator vane stages.

As

its name implies, the air is being compressed in a direction parallel to the

axis of the engine.

This

axial compressor has the advantage of being capable of very high compression

ratios with relatively high efficiency with respect to the British centrifugal

compressor engines developed in the same years.

COMBUSTION

CHAMBER:

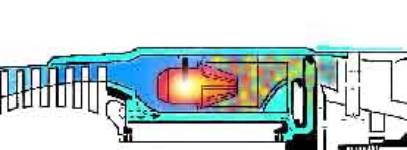

In

the Jumo 109-004A/B/C/D engines there are six combustion chambers located around

the structure.

The

combustion chamber is able to move axially as a consequence of the thermic

dilatation that happens during ignition.

The

first stage consists in the separation of the primary and secondary

air as shown in the figure:

Then

the fuel is forced to go out against the stream, is mixed with the primary air

and ignited. A bulkhead prevents the combustion chamber from being subject to

the high

temperatures caused by the hot exhaust gases. After they have passed through the chamber, the secondary air is

added to them to prevent the overheating of the turbine.

TURBINE

CONSTRUCION:

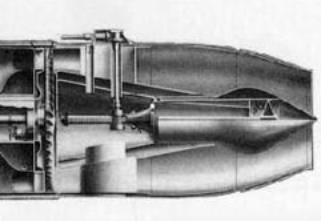

The

turbine wheel is one of the most highly stressed parts of the Jumo 109-004. The

turbine assembly is made up of two main parts, the disk and the blades. The disk or

wheel is a statically and dynamically balanced unit of specially alloyed steel

containing mainly Chromium, Vanadium but also Manganese, Magnesium, Silicon, and

Carbon. The

turbine wheel is one of the most highly stressed parts of the Jumo 109-004. The

turbine assembly is made up of two main parts, the disk and the blades. The disk or

wheel is a statically and dynamically balanced unit of specially alloyed steel

containing mainly Chromium, Vanadium but also Manganese, Magnesium, Silicon, and

Carbon.

The

blades are attached to the disk by means of gudgeon pins designed to allow for

different rates of expansion

between the disk and the blade while still holding the blade firmly against

centrifugal loads.

The

61 blades of the Jumo turbine engine are made up of stainless steel containing

mainly Nickel and Chromium (0.15%C; 0.7%Si; 0.6%Mn; 1.7%Ti; 30%Ni; 19%Cr). The

buckets are empty inside and supported by an air cooling system.

JET

NOZZLE:

The

nozzle of the Jumo 109-004 is variable, so as to maintain sufficient efficiency at low

speed. In the part near to the engine there is a device that can move along the

structure of the engine for 0.20 meters, restricting the section of the nozzle.

By doing that, the pilot can also control the temperature of the exhaust

gases. The

nozzle of the Jumo 109-004 is variable, so as to maintain sufficient efficiency at low

speed. In the part near to the engine there is a device that can move along the

structure of the engine for 0.20 meters, restricting the section of the nozzle.

By doing that, the pilot can also control the temperature of the exhaust

gases.

|